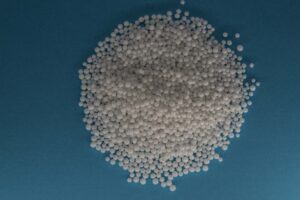

Alumina hollow ball/ Alumina bubble

Its main raw material is high quality alumina powder. After melting through the electric arc furnace, blowing and then instantaneously cooling in air, the alumina bubble will have the characteristics of light weight, closed hole and high temperature resistance. It is the ideal heat-insulated filler for high temperature furnaces, as well as the high quality aggregate for high temperature light refractory castable.

Alumina bubble as the main material can be made into various shapes of products, with the service temperature 1800 ℃. The finished products have the high mechanical strength, which is several times higher than general light products, while its bulk density is the half of corundum products.At present the alumina bubble is mainly used in the high temperature furnace / industrial furnace insulation, such as petrochemical industrial gasifier, carbon black industrial reactors, metallurgical industrial induction furnace and other high temperature, ultra-high temperature furnace. The energy saving effect is very good.

APPLICATION

Alumina bubble bricks are mainly made of alumina bubble and can be made into various shapes

Specification

Physical Properties and Chemical Composition | |||

Index | Standard | ||

Chemical Composition(%) | Guarantee value | Typical value | |

AL203 | ≥99 | 99.34 | |

SiO2 | ≤0.2 | 0.15 | |

Fe2O3 | ≤0.1 | 0.06 | |

Bulk density(g/cm3) | 0.5-1.0 | 0.75 | |

Percentage of broken (%) | ≤15 | 12 | |

Fire resistance temperature(°C) | 1800 | ||

Particle size | 0.2~0.5mm、0.5-1mm、1~3mm、3~5mm | ||

Inspection standard | GB/T3044-89 | ||

Application | High temperature lightweight castable and high temperature furnace insulation filler | ||

Packing | Inner plastic and external weaving 25KG/bag (can be customized according to customer requirements) | ||